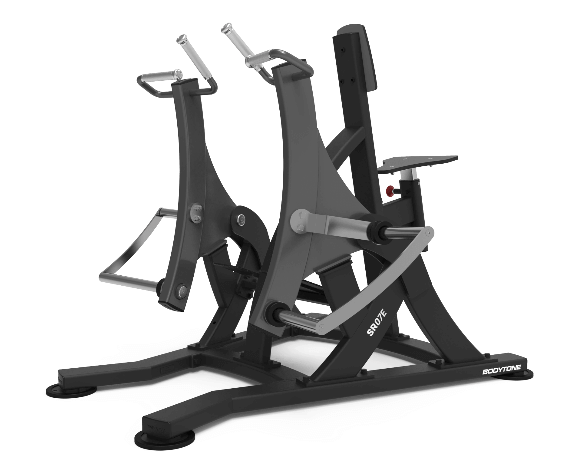

Bodytone Solid Rock Outdoor Range

Row Bodybuilding Machine

Solid Rock’s professional bodybuilding machines stand out for their design and innovation. They have a well-taken care of aesthetics and are equipped with the latest technology. Now we present the new outdoor range. Solid Rock equipment uses technology from the automotive industry so that the structure and paint can withstand up to 10 years or more. A guarantee of quality, resistance and durability.

STRUCTURE

Steel tube of 110 x 52 mm with 3 mm thickness. Welded according to UNE 10219 regulation, quality S-275-J0H. Enriched and optimized to maintain a constant section in the bending process, avoiding more sensitive areas with a low breaking rate. Cold bending process, by means of a 4-roller system; avoiding any deformation in the process and maintaining their physical characteristics in the whole piece.

PAINTING PROCESS

5 layers of paint. 200 microns Steel pickled and stabilized by total immersion of the pieces in different degreasing solutions to guarantee a perfect and complete cleaning of the base material. Antioxidant zinc phosphate primer to ensure adequate insulation from internal oxidation and good paint adhesion. 3 final layers of epoxy polyester paint, special exterior drying at 240ºC. Surface layer of polyester protective varnish.

AXLE SUPPORT

10 mm thickness plates cut by laser with another 10 mm plate for reinforcement, for a smooth movement without looseness or torsion produced for the continuous usage or loading.

AXLES

Machined stainless steel shaft AISI 316, austenitic steels more resistant to corrosion with respect to class A2 thanks to the presence of molybdenum, which allows use in aggressive environments such as boiling sulfuric acid or in environments containing chlorides up to certain levels. Widely used in cellulose, food and marine industries.

WELDING

Perimeter closed welding in structural points and union plates.

SEAT AND BACK

Backrest, seat in PENCIL FENOLICO special exterior of 25 mm. High resistance to climatic changes, abrasion and humidity.

GRIPS

Anodized ALUMINUM, knurled favoring grip.

SCREWS

In stainless steel AISI 933, tensile strength of 700 Newton / mm2.

BACKING AND SUPPORTS

Supports in tube of 50mm diameter and 3mm thickness in stainless steel AISI 316, special anticorrosion in marine environments. Closed disc system with vandal protection.

Reviews

There are no reviews yet.